ESI’s Composite Simulation Software Presented at JEC World 2017

Paris, France – February 8, 2017 – ESI Group, leading innovator in Virtual Prototyping software and services for manufacturing industries, will be taking part in JEC World 2017, the world’s largest trade show for the composite industry. From March 14 to 16 in Paris, France, ESI will demonstrate its innovative simulation software addressing multiple industries – from automotive to aerospace, marine and energy – and aimed at reducing or replacing costly physical try-outs with the help of virtual prototypes. With ESI PAM-COMPOSITES, composite manufacturers can master their manufacturing processes and get their products right the first time. Then, with ESI Virtual Performance Solution (VPS), they can evaluate early in their development process the performance of those parts “as built“ and assure they meet the stringent requirements set by customers or end-users.

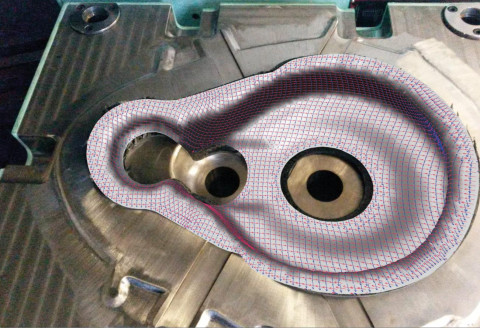

Thermoforming of thermoplastic electric transmission housing with ESI PAM-COMPOSITES Courtesy of ARRK | Shapers

In the automotive and aerospace industries, where harmful gas emissions and fuel consumption are heavily regulated, weight reduction goals often involve multi-material strategies that integrate light materials. “Lightweighting” is the reason why industrial manufacturers and their suppliers are investing so much time and effort to incorporate composite materials in their new product design, while not sacrificing strength and durability. Unfortunately high manufacturing costs and hard-to predict material behavior are challenges when seeking to use composites for structural parts. Here, in the era of digital transformation, Virtual Prototyping provides an opportunity to address the difficulty.

This winter at JEC World 2017, March 14-16 in Paris, France, ESI will present the new version of ESI PAM-COMPOSITES, the leading solution for simulating the manufacturing of continuous fiber composites. The software helps engineers identify and address defects early in their product development cycle; at a time when it is easier to fine-tune the production process. Using PAM-COMPOSITES, process engineers can analyze and optimize individual manufacturing operations, and then link these operations by transporting material detail – such as fiber orientation, curing degree, and temperature - from one operation to the next. Progressively building a virtual prototype of the “as manufactured” part they can correct, optimize, or validate processes – including draping, thermoforming, Resin Transfer Molding (RTM), infusion or curing – to minimize manufacturing defects, ensure reproducibility, improve the overall quality of produced parts, and decrease development costs.

Using a high fidelity virtual prototype engineers can virtually assess product performance with great precision. Here, ESI’s flagship software Virtual Performance Solution (VPS) empowers engineers to test their virtual prototype across all domains of performance, enabling them to run virtual crash tests, and predict strength, durability, or vibration behavior, while benefitting from use of a single core-model. VPS is a powerful solution, helping designers to ensure the performance of multi-material parts or products; preventing costly recalls without resorting to conservative design margins.

At JEC World (Hall 6 - D53), ESI will offer live demonstrations and presentations on the following topics:

- Composite Thermoforming Simulation

- Virtual Manufacturing of a Fuselage Panel

- Composite Part Case Study: from Manufacturing to Performance

- Design, Assembly and Performances of Multi-material Composite Parts

Partners and customers will also introduce collaborative projects that leverage ESI’s simulation software:

- Aimen Technology Center: Methodology for Thermoplastic and Metal Joining as part of the COMMUNION H2020 project

- ARRK Shapers: Project of Thermoplastic Composite Gearbox for an Electrical vehicle

- Coriolis: How to Optimize the Forming & Injection of Preform made by AFP

- École Centrale de Nantes (ECN): PhD project; Dual-scale Flow in RTM Injection

- IRT M2P: Highlights of the FASTFORM Project for the Industrialization of Preforming Process

- Rescoll: Composite Material Characterization

- TU Desden: Development Processes for Composite Components

- USCAR: New Design of a Composite Bumper System to Ensure Performances

Dr. Pilar Rey Rodríguez, R&D Project Director at Aimen Technology Center and Dr. Patrick de Luca, Manager of ESI’s Center of Excellence for Composite Materials, will also present a paper entitled "Optimization of multi-material parts performances thanks to new metal/thermoplastic composite joining technology" at the JEC Conference on Wednesday, March 15 from 2:00 PM to 4.45 PM in the Workshop Area, in the session “Current Trends in the Automotive Industry”.

Find out more about ESI’s attendance at JEC World 2017, March 14-16: http://www.esi-group.com/company/events/2017/jec-world-2017

For more information about ESI PAM-COMPOSITES please visit www.esi-group.com/Composites

For more information about ESI Virtual Performance Solution please visit www.esi-group.com/Lightweight

To follow ESI Composite Simulation news: https://www.linkedin.com/company/esi-composite-simulation

For more ESI news, visit: www.esi-group.com/company/news

ESI Group – Media Relations

Celine.Gallerne [at] esi-group.com (Céline Gallerne)

+33 1 41 73 58 46