ESI presents its Casting Simulation Suite ProCAST 2015 at GIFA

Paris, France – June 18, 2015 – ESI Group, pioneer and world-leading solution provider in Virtual Prototyping for manufacturing industries, announces its participation in GIFA, June 16 – 20, 2015 in Düsseldorf, Germany. The 13th edition of the world’s most important International Foundry Trade Fair provides the perfect opportunity for ESI to showcase the latest advances of its flagship casting simulation software ProCAST, created 25 years ago. Founded on the physics of materials, ESI’s solutions help manufacturing companies test their products virtually; eliminating the need for physical prototypes by virtually building and testing prototypes of components, parts or even complete products. Not only do ESI’s numerical solutions help industrial clients manage product performance, they also help companies save time and money during product design and development.

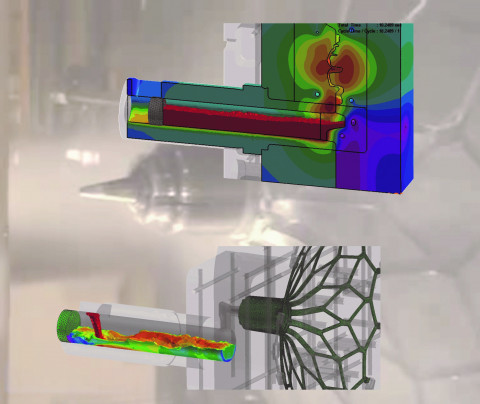

Comprehensive High Pressure Die Casting Process Simulation. Courtesy of Mofopress.

Celebrating its 25th birthday this year, ESI’s Casting Simulation Suite, ProCAST, provides a complete set of solutions for the foundry industry. ProCAST enables predictive evaluations of the entire casting process, including filling and solidification defects, mechanical properties and complex part distortion. It enables rapid visualization of effects of design changes and provides a basis for correct decision-making, from the earliest stages of the manufacturing process design. ProCAST enables the modeling of all casting processes for all castable alloys, and also addresses other foundry relevant manufacturing processes like core blowing & heat treatment.

During the GIFA tradeshow, visitors to ESI’s booth have the opportunity to receive a complete overview of ESI’s latest advances in casting process simulation with the newly released ProCAST 2015. Along with other important developments, the new version of the solution embeds the QuikCAST solver into Visual-Environment, enabling consistent user access to two different technologies, Finite Element Method (FEM) and Finite Difference Method (FDM), from a single platform. ProCAST 2015 also introduces an Optimization solver which allows users to set-up Design of Experiments (DOE), to test for robustness and to optimize their casting processes, aided by standard intuitive workflows.

As part of customer meetings during GIFA, ESI casting simulation experts examine the specific challenges that companies face, and illustrate specific solutions through tailored software demonstrations. The ESI booth is staffed by ESI’s multinational and multilingual casting team, joining GIFA from Europe, North America, China, India and Japan.

At the GIFA Congress, which runs parallel to the trade show, ESI is presenting a paper entitled “Modeling and Optimization of Part Ejection in Magnesium High Pressure Die Casting” jointly with their customer, STIHL, Germany. The paper reveals the state-of-the-art modeling capabilities of ProCAST through practical examples.

Where to meet?

ESI booth is located in Hall 11/Booth H56.

To arrange your software demonstration, please email Christina.Theuerkauf [at] esi-group.com'; // --> //--> , Marketing Programs Specialist, ESI Group.

For more ESI news, visit: www.esi-group.com/company/news.

Connect with ESI on LinkedIn, Twitter, Facebook, and YouTube

ESI Group – Media Relations

ESI Group – Media Relations

celine.gallerne [at] esi-group.com (Celine Gallerne)

+33 1 41 73 58 46