Finding Success With Composites Through Virtual Manufacturing

Worldwide

DATE: February 11th, 2020

TIME: 3pm (CET - Paris Time) / 9am ET

LENGTH: 1h

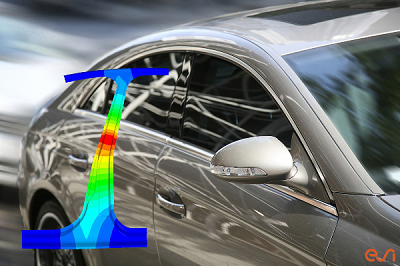

Composite structures are experiencing rapidly emerging opportunities.

Automakers strive to reach their goals for extending the range of electrified and traditional vehicles without sacrificing strength, stiffness, or performance. The aviation industry is seeing an increased need for larger volume production of components used throughout the aircraft. Moreover, if the buzz about personal airborne mobility and autonomous air logistics are not just fads, they will stress previous methods as production volumes shift closer to automotive numbers than aero numbers.

Join us as we discuss the challenges facing the product and process engineering for higher volume composite parts. We will be addressing parts and components ranging from large structures to smaller components, from low production volumes to more mass-produced objects.

Topics we’ll explore:

- When part design and materials design intersect

- Composites value stream and life cycle

- Validating product performance with manufacturing intent

- Trends and industry solutions

Bonus:

Examples of how top companies from Automotive, Aerospace, and Marine are finding success with composites simulation tools.

PRESENTER

Eric Kam

Eric Kam is the Marketing and alliances director, Manufacturing Business Channel with ESI-Group. He supports Extended Reality solutions for Product Engineering/Integration, Virtual Build & Maintenance. A digital transformation advocate, he seeks to democratize simulation technologies in CAE, FEA, and CAD. Eric is a longtime member-leader of SME technical communities, with a BSME from Michigan Tech.