KION Enhance Compatibility and Sustainability by Digitalizing Industrial Product Design with IC.IDO

About KION

Across more than 100 countries worldwide, KION solutions improve the flow of material and information within factories, warehouses, and distribution centers.

With international brands like Linde Material Handling, STILL, and Baoli, as well as regional brands Fenwick and OM, KION stands for exceptional technology and service expertise for forklift trucks and warehouse handling equipment around the world.

The Challenge: How to Streamline Product Development

KION was looking for a way to minimize the creation of physical mockups, eliminate design loops, and foster early-stage communication.

Additionally, KION wanted a solution that would enable the early visualization of 3D data, swift access and a seamless interface with CAD tools, preliminary evaluation of truck concepts in a 3D model, and verification of compatibility among individual components within development teams.

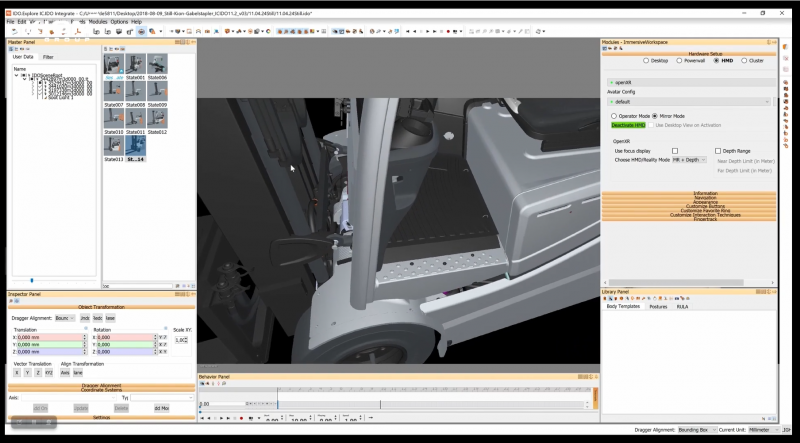

The Solution: Virtual Product and Process Validation in IC.IDO

IC.IDO provides a virtual environment for building, operating, and maintaining products without physical construction, offering a 1:1 scale of design concepts in immersive Virtual Reality. It allows users to experience and address unforeseen challenges in assembly, operation, and maintenance before finalizing decisions.

KION has successfully integrated IC.IDO into its design department, leveraging the tool to virtually assess and validate various concepts such as seat configuration, variable steering systems, and the exchange of batteries and other serviceable parts.

KION has also extended the use of IC.IDO to the prototype workshop, where it is used to virtually build a forklift step-by-step, before then assembling an initial physical prototype.

Additionally, KION has been able to streamline their documentation by automatically generating a protocol from each session, reducing manual reworking efforts when included early in the design process.

Image courtesy of KION Group

The Benefits: Efficiency and Agility

Image courtesy of KION Group

The use of IC.IDO has provided KION with a multitude of benefits in their design and analysis process. The software allows for the comprehensive consideration of variants with minimal preparation work involved, enabling a thorough exploration of design possibilities.

Conducting this analysis early in the design process provides KION with valuable insights and avoids potential issues downstream, ultimately enhancing quality whilst reducing the number of change requests that would typically follow a physically built prototype. By working with virtual models, no real vehicle needs to be blocked for analysis, eliminating the constraints associated with physical prototypes.

Overall, these features contribute to a more efficient and agile design workflow, optimizing the entire product development lifecycle.

Looking to the future

KION aims to deploy IC.IDO company-wide for collaborative development, transforming their product development by reducing reliance on physical prototypes, minimizing development loops, and enhancing early communication.

The software is envisioned as a key tool facilitating technical collaboration, marketing efforts, and efficient information exchange between departments, with the ultimate goal of integrating IC.IDO into the entire Product Creation Process for a unified approach to product development.

Image courtesy of KION Group