Empower Automakers to Engineer and Manufacture Multi-Material Assemblies with Confidence

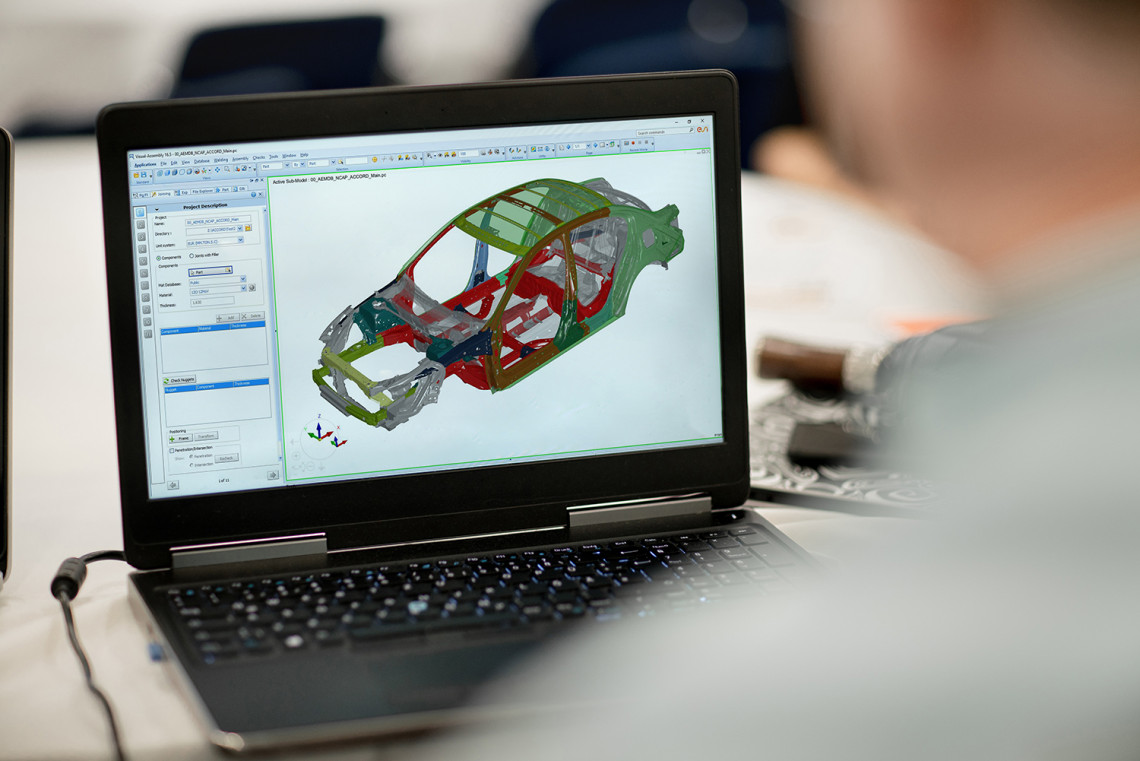

Virtual Prototyping represents an end-to-end approach for early validation of material and design choices, manufacturing and assembly process strategy, with significant benefits over the complete body development cycle.

Automotive companies strive to develop disruptive and sustainable mobility devices. Their carbon reduction objectives mostly translate into weight reduction targets ─ which conveniently fits the bill for increasing EV range. Introducing new materials and processes can be very tricky with regards to feasibility, as much as for final product performance that no one is ready to jeopardize. Not to mention cost – product development involving new materials and processes over which you have no experience is inevitably risky and full of surprises. Read on to learn about feasibility assessments, assembly process prediction, performance validation – all-virtual, cost-effective and “first time right”.

Shifting from single-point numerical simulation to end-to-end Virtual Prototyping

Over the past decades, numerical simulation has been instrumental in allowing OEMs to evaluate manufacturing feasibility and to assess and validate a design’s performance. However, body manufacturing decisions are made relatively late in the process, after the design freeze, and automakers still rely heavily on physical testing. Often, engineers detect body assembly distortions too late in the process (image 1).

The ambition to frontload manufacturing decisions is not new. But the design-to-cost requirement brings an additional push. Indeed, the best practice is to find an optimal design as early as possible and to validate it in the engineering phases, and this in a highly predictive manner, to avoid costly prototypes and late design changes during manufacturing pre-production validation.

Achieving such an optimal design through a purely digital approach is not straightforward. Two main aspects need to be accounted for to ensure a fluid journey until serial production (image 2).

Single Parts Manufacturing: Detailed simulation of single-part manufacturing has been established in the industry for many years. However, typically it comes later in the workflow because engineers need to define various tool environments first. With the rise of advanced mix-materials, automakers, need early confidence to make the right decisions about which material works best at which place. Thus, it is very important to be able to estimate the manufacturing feasibility since the beginning, when the first CAD data and bill of material (BOM) are generated. Virtual Prototyping allows engineers to consider all this information in early development phases and therewith improving the predictivity of the function and performance validation as well as the assembly process simulation – even prior to process tools and dies definitions.

Joining Process: The possibilities to join multi-material assemblies are numerous. To find the right match, it is crucial to accurately model and simulate the joining process in order to transfer the connection strength into crash and durability optimization. In addition, engineers need to account for the impact of the joining process on the parts’ geometries in order to predict assemblies’ quality. The final target is always to have the best predictivity as early as possible, with minimum computation time.

In the later pre-production validation phase, the first physical parts would be sent over typically from different suppliers and locations to OEM assembly plants in order to check final assembly tolerances and quality. To overcome these costly logistics, Virtual Prototyping allows engineers to use instead 3D scans of the single parts plus the joining process impact as input for their assembly simulation. Consequently, parts and assemblies tolerances deviations can be anticipated and costly trial-and-error phases avoided.

Furthermore, 3D scans can even be replaced now by digital results of manufacturing processes, like stamping. As a consequence, distortions and tolerances in body and chassis, as well as perceived quality in class A panels assemblies, can be analyzed and predicted already in early development phases, ensuring the end product can be produced and assembled at the highest quality standard within the specified tolerance range.

In a nutshell: Virtual Prototyping represents an end-to-end approach, for early validation of material and design choices, manufacturing and assembly process strategy, with significant benefits over the complete body development cycle. It empowers automakers to effectively validate all the leading lightweight material candidates for vehicle structures safety-critical components and to associate the optimum joining processes to achieve assemblies at the best performance/cost/quality ratio.

This robust foundation brings early confidence before moving to the physical world with clarity about the right production strategy, which is finally virtually validated prior to production with a constant link to function and performance validation. This paves the way for a digital Body factory in which automakers can progress towards zero physical prototypes, ultimately shortening the overall product development cycle and minimizing its cost and time to start of production (SOP).

Discover our software solution here.

Join our upcoming Multi-Material Joining Assembly Webinar Series to find out how to couple the engineering and the manufacturing world in order to make the right choice as early as possible.

Customer Success: Nissan reduced engineering lead times for new lightweight material by as much as 50%

To address the weight reduction objectives of Nissan’s Green Program, the Japanese OEM has been investigating mixed material use (aluminum, steel, and composites assemblies). Nissan engineers used ESI simulation solution for composites manufacturing to develop a new process method of injection molding and compressed molding, bringing significant efficiency gains for their production lines. By trading the usually long and costly trial-and-error period for developing a new manufacturing process with numerical simulation, Nissan’s engineers managed to make early decisions on lightweight material types, while securing design requirements and production goals. By their estimation, they succeeded in reducing engineering lead time by as much as 50%.

In terms of manufacturing results: just before ESI kicked off its first-ever ESI Live conference back in November 2020, Nissan publicly announced their breakthrough in carbon fiber parts production. They went from producing a Carbon-Fiber Reinforced part in two hours down to 2 minutes, reducing production time for a single molding by 80%. This technological agility also allows Nissan to produce complex part shapes enabling an average weight reduction of 80kg per vehicle.

Such an achievement became possible not at least thanks to the ability of confident decision-making and early optimization and thanks to synchronized activities in both design and manufacturing engineering for forming, heat treatment, joining and assembly processes.

Matthieu Niess joined ESI in 2020, bringing with him his expertise in the automotive industry for both Body Engineering & Manufacturing, with a specialty for multi-material and electrification challenges.

During his 10 year experience with a major automotive Tier 1 company, Matthieu has been actively leading various Body-In-White product-process projects for rank 1 OEMs, with a constant focus on helping customers reaching an optimum balance between mass, performance and cost. This deep understanding of the car body industry provides him with a breeding ground for his current projects.

Matthieu holds a Post-Graduate Degree in Mechanical Engineering from the French Institute of Advanced Mechanics (IFMA) in Clermont-Ferrand, France.