Aircraft Interior Design Just Got More Challenging

Packed planes are good for business and the environment (more people on one airplane means fewer planes in the air). But in the midst of a global pandemic, cramming people on-board raises new challenges for engineers designing and analyzing aircraft interiors.

Airlines constantly face the necessity to increase capacity in economy class. Having more people on board is not only better for the airline's business but also better for the environment, as fully packed airplanes mean fewer airplanes in the air. But in the midst of a pandemic, packing passengers together raises new challenges for engineers designing and analyzing aircraft interiors.

We meet two such engineers at ESI. Christian Marca, Product Manager from Marseille, France, and Trevor Edwards, Vibro Acoustics Global Business Development from the UK who are steeped in-cabin comfort and Vibro-acoustics.

Noise

If you have heard a military plane take off or fly overhead, you know how loud a jet engine can get. The noise will have you bleeding from the ears, well in excess of 100 dB. By contrast, a commercial airplane may not even wake up the baby, whether that baby is sleeping inside the plane on a bulkhead bassinet or the family naïve enough to have bought a house in the flight path of a major airport. Commercial airplane engines are muffled, their interiors stuffed with noise-absorbing materials. The noise management is so effective that the loudest noise could be the rattle of the overhead storage space compartments.

You, the engineer, wonder how the stowage bins are missing an isolator. There is probably a flat panel that is resonating from engine frequencies, or perhaps wind noise. Most likely, it is the former. Perhaps the vibration analysis was skipped.

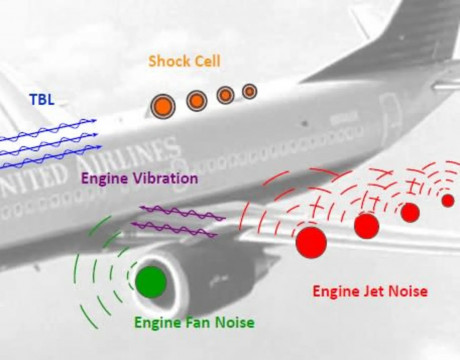

Doing more than wonder are hotshot engineers who specialize in aircraft acoustics and the structural integrity of cabin fixtures. Trevor’s job is to consider excitations from jet engines and wind noise. He struggles to boil down a career in Vibro-acoustics into a short interview—but does so marvelously. Trevor breaks down the noise sources in a commercial jet aircraft into three types.

Engine noise is that which is emitted by the fan and turbine blades but also from the combustion and hot exhaust gases. The noise can be heard directly from the source, but the vibrations from the engine are also transferred into the airplane by the airframe structure and can be picked up as resonant frequencies of fixtures in the aircraft cabin—such as the rattling of overhead stowage bins. Engine noise is highest during takeoff. Aft-mounted engines contribute more vibration than engines strapped on under the wing.

The aerodynamically piercing smooth overall shape of a commercial jet does not hold true in the details. Look closer and you will see all the objects that mar laminar airflow, and all the things that stick out or are sunk in, such as rivets, antennae, or probes. The big unsightly radome over the satellite antenna providing you with Wi-Fi may be forming shock cells from the perturbations in the boundary layer, says Trevor.

If you had envisioned a noiseless, laminar flow over the aircraft exterior, you will be surprised to find that enough turbulence occurs in the boundary layer to make it the main source of interior noise in the aircraft cabin during cruise conditions. That turbulent boundary layer (TBL) enters the aircraft through the skin and then into cavities, through structural frame members, isolators, into trim panels, through floor beams, and into the floor—and that noise is heard everywhere inside the cabin.

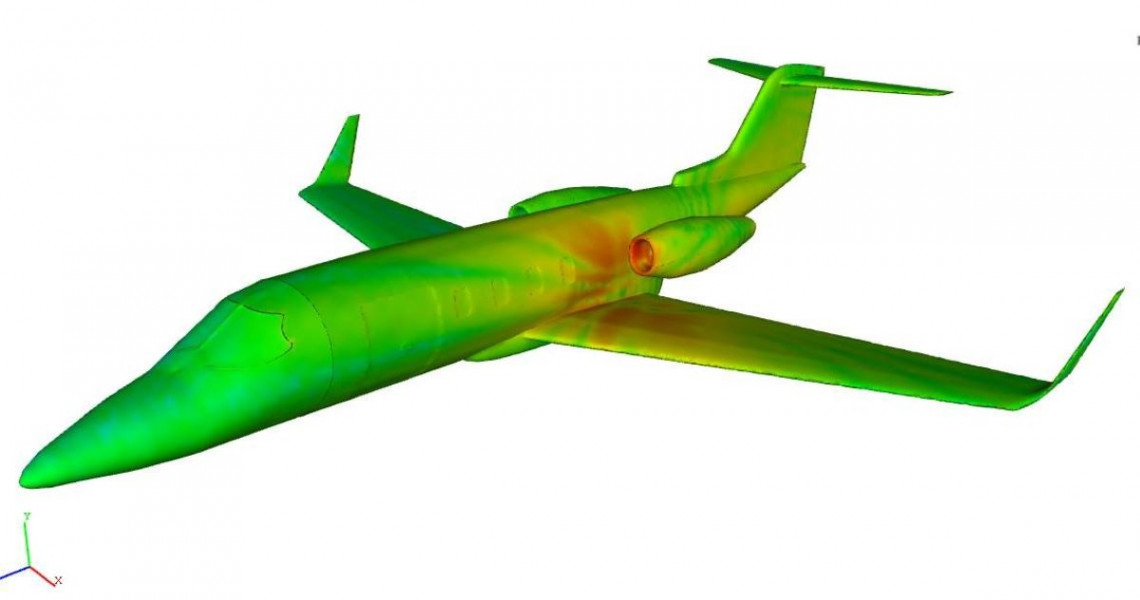

“We can model all these components,” says Trevor. “Including stowage bins, the skin itself, stringers, sidewall, floor panels windows, and more. Their structural properties are used to determine how they will handle the noise and vibration.”

Sound is a Safety Issue

So, what if your Adele doesn’t sound as good through your EarPods in the air as on the ground?

The study of a “sound zone” around the passenger is anything but trivial for Trevor. It’s a matter of safety, too; you must be able to clearly hear the announcements the pilots and crew are making, he says.

The study of acoustics can get lost in overwhelming detail. Calculations done at the level of rivets or air molecules for a commercial jet aircraft will tax a supercomputer.

"Analysis done with discretized models, either finite or boundary elements, are computational nightmares," says Trevor. "Methods such as statistical energy analysis (SEA) offer a computationally efficient method for high-frequency analysis. Ray tracing extends this capability to include directional effects to solve for sound."

"Ray tracing can handle multiple compact acoustic sources including directivity," he adds. "You can place arbitrarily shaped obstacles and judge the effect of noise control treatments and their energy diffusion. With ray tracing, you can use different reflection models to represent the acoustic field. Multiple order diffraction has been implemented.”

With ray tracing for sound, you start with a CAD model of the outside of an aircraft, and from this, create models that include noise control treatments. You input your various sound sources and run the ray-tracing analysis. The results of ray tracing can be used as loads for an analysis of the aircraft interior with either FEA, BEM, or SEA simulation.

“With ray tracing, we can analyze for speech clarity, predicting the response due to an instantaneous excitation,” says Trevor. “We can calculate the effect of background noise and noise control treatments. Ray tracing can predict speech transmissibility and find optimum speaker placement.”

So those safety and emergency announcements can be heard everywhere inside the cabin?

“Yes. We have implemented direct and indirect strategies to evaluate speech transmission. Our latest version can deal with reflections of more complicated shapes,” Trevor adds.

The Structural Simulations

That you can wonder about the rattling overhead compartments is testament to others, and far more serious threats being dealt with. You don’t worry about your airplane seat collapsing under your weight like a flimsy lawn chair—even during a hard landing. That seat has undergone some serious simulation and faced the worst conditions, such as 16 Gs in a crash landing. Don’t worry, it was only crash dummies—virtual dummies in ESI’s world—restrained only by lap belts and with their heads slamming onto walls, and not the softer seat in front of them.

It’s because of simulation that the seat can survive crashes even when strapped on to an overweight passenger—and also why you have little room for your feet or knapsack. In first-class, where you can really stretch out, seat design may take into account an elaborate entertainment system, lights, and power.

Enjoying the rigid but light seats are airline accountants, who translate each ounce saved into fuel savings and each extra seat into revenue. You’ve thought that every time your knees have scraped the seat in front of you. You’re sure they would have you standing if they could.

The accountants have already thought of this. The average seat-to-seat distance has shrunk by three inches since 1978, according to the New York Times. Airbus has also revealed a stand-up concept “seat.”

Perhaps the biggest challenge is invisible: the air in your precious little personal space. That air might be shared by one and all on the same flight, blown about by air vents overhead and underneath, part of the ECS (environmental control system). The ECS is also a source of noise. Hydraulic pumps and electronics also emit noise.

While climate control is limited in coach class, first-class and business-class passengers have a bit more control of their environment.

A Class Struggle

As we shuffle through the first-class cabin on our way to the back of the plane, we can’t help but sigh. First-class can be a study in lavishness, whereas economy class is a study in packing efficiency. Thick, padded seats with speakers for maximum entertainment pleasure and lie-flat seats are cocoons of comfort. ESI software can model the electromechanical system composed of structure, wires, motors, and entertainment systems with speakers.

To help simulate the environment is ESI’s VA One, a multi-physics sound simulation specialized for aeronautical application. It includes:

- 2D to 3D automatic SEA model building

- Speech clarity

- Insulation optimization

- Aerodynamic and vibration acoustics

- Composite modeling

- Fuselage wall transmission loss

Who is using VA One? Who isn’t? says ESI. Indeed, the list of aviation companies using ESI’s software is almost complete with Boeing, Airbus, Dornier, Cessna, Bombardier, Bell Helicopter, Sikorsky, NASA, and Augusta Westland. Missing is McDonnel Douglas, and Learjet is not mentioned in name but is part of Bombardier.

ESI software also addresses the comfort of the pilot, the most important person on the plane (after you, of course). A model of the pilot is able to determine position and comfort for the long haul, as well as ensure controls are within reach.

What’s Wrong with Testing with Humans?

The current development process to create an aircraft interior has its advantages and limitations. The advantage is obvious: nothing simulates one human with as much fidelity as another. But humans being so expensive, come in all shapes and sizes and are of all ages – from the babies in child carriers to the elderly in wheelchairs. Getting the proper selection during a live comfort test is a casting nightmare. It’s so much easier to dial up the girth of a digital passenger, or increase their height, or limit their mobility.

Using a digital human allows the aircraft interior designer to have shorter delays, iterate more and be more innovative, says Christian.

A digital human, just like a real one, can be used for determining areas of high pressure on seats—the spots that become increasingly irritating in direct relation to the length of the flight—but the simulation can span a wider range of dimensions quicker than with a few human test cases.

“ESI’s Interior application provides models of various morphology,” says Christian. We supply a database of virtual human specimens. They are frozen in common positions, such as seated with hands extending towards controllers for pilot simulation, but they can be moved to different postures and positions. They can be used to see the pressure hot spots on seats, for example.”

“Having a virtual model makes for complete repeatability,” adds Christian.

How much of a pain in the butt is the dreaded middle seat? Find out with ESI software that shows pressure points on the seat cushion of a 50th percentile male European economy class passenger. (Picture from Aegats Conference 2016 Proceeding.)

ESI software promises more comfort with aircraft interior design software that localizes the environment to individual seats, giving even economy class passengers smarter climate and light control that depends on the detection of a passenger, by controlling the air vents and overhead lighting.

The human prototype, unlike the flesh and blood version, can have its temperature dialed up and down as well as easily assess the comfort level with body zones. The digital seat can model passive and active elements, such as heating coils or cooling channels, should they ever exist on airplanes. The overall cabin air can be simulated for heating and cooling including radiation, and energy consumption. The human, their seat, and the cabin are coupled so that heat is exchanged between them.

Certification

The airline industry faces changes in certification from both the FAA and its European counterpart, the EASA.

- The test dummy will change from FAA Hybrid II to FAA Hybrid III

- A new composite seat structure being planned for will have a certification protocol

- Simulation is being introduced in the certification process

The seat certification is becoming increasingly challenging, says Christian. The process is too costly and too demanding. It is stifling innovation. As a result, passenger comfort is tested too late in the design process.

By the time humans are called in to test prototype seats, it may be too late to make changes for comfort. Aircraft manufacturer Boeing is pushing for a “smart” certification that involves more virtual prototyping, with a NAFEMS presentation that listed 15 to 19 tests in the current certification protocol.

The cost of testing has increased greatly over the years because of the increasing demands for certification.

“That is a project cost that can be alleviated with virtual prototypes,” says Christian.

The process can be automated, says Christian, and that will save time and reduces delays. Shape morphing and optimization can be done with software. Shapes and materials can be optimized. Iterations can happen much quicker which can only increase the chance of a better design.

For example, take the head injury specification (HIC), says Christian. “We were able to use a virtual prototype to determine the effectiveness of an airbag for two pilots side by side. Without the airbag, the analysis showed an HIC is 876 while the adjacent pilot suffered an HIC of only 115.”

One company that uses ESI software for aircraft seats is the French company Expliseat SAS. Designing its titanium seats virtually helped them “win the race.” The company credits ESI for being able to quickly redesign after physical testing exposed a design flaw.

Originally published by Engineering.com

For more information from ESI about cabin and cockpit acoustics, click here.

For more information from ESI about cabin and cockpit interiors, click here.

Learn more about ESI Interior Solution

Caroline Borot currently serves as the Head of Marketing Strategy, Product Marketing, and Business Development for ESI Group’s Engineering Solutions. After joining ESI group in 2000, Caroline has served several positions from technical support management, project management, and product manager on a variety of manufacturing and engineering products. Previously, Caroline worked in an SME software company as technical support and pre-sales function. Caroline is ingénieur civil des mines with a background in Material & Mechanical Engineering.