J. Walter Miller Company choose ESI’s casting simulation software to make a profound technological evolution

J. Walter Miller Company selected QuikCAST, ESI’s casting simulation software, to fully reconfigure its complex castings in a minimum period of time and at a minimum cost during its technological transition from manual green sand squeeze molding to fully automated molding machines.

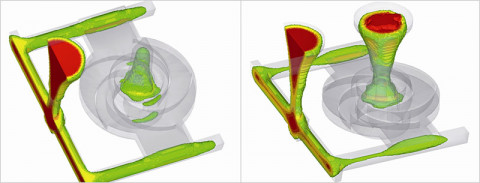

On the left: Closed riser and cored hub design – Shrink pocket shown in wear ring. On the right: Open riser, solid hub design – No shrink pocket in wear ring.

J. Walter Miller Company (JWMC) produces brass and bronze castings for the fire protection, pumping and valve industries. Both leaded and non-leaded alloys are poured on a daily basis and give JWMC a unique mix of capabilities. Historically, JWMC has specialized in small castings but is growing into larger sizes with the recent acquisition of the DISA Match 130, a match plate molding machine. As a result, each squeezer pattern needs to be converted to run on the new equipment.

For a foundry producing non-leaded pump components, impellers are a main challenge because of the heavy and thin sections of the casting. Indeed, JWMC’s impeller castings exhibited shrink porosity and voids in the hub when machined at the customer’s facility; thus, the riser at the hub area required redesign.

The initial design, prior to the use of QuikCAST software, lead to the addition of a core in the hub, to reduce the amount of liquid metal required to feed the hub during solidification, showing no defect after boring. However, a new defect began to appear in the wear ring section of the casting.

At this time, JWMC decided to explore the use of ESI’s QuikCAST casting software, enabling the simulation of the entire casting process from filling to solidification including defects prediction, to determine the cause of this frustrating new defect. Thanks to QuikCAST, JWMC was able to find a new design configuration eliminating the shrink during machining. As a result, QuikCAST enabled JWMC to reduce the number of iterations required to reconfigure patterns, reduce porosity in finished castings and explore opportunities for yield improvement. JWMC’s customer also witnessed a dramatic reduction of scrap in the machining process, which contributed to large cost savings for both the customer and JWMC.

“This problem would have taken about 12 weeks and $6,000 in pattern changes plus countless hours of machine time to solve using conventional trial and error methods”, declared Dan Rudolph, Quality Engineer at J. Walter Miller Company. “With QuikCAST, we can easily solve similar problems in 2 weeks and produce a good pattern the first time. We have used simulation on about 20 parts to date and the simulation results are similar to what we see in the shop."

To read the full story about J. Walter Miller Company and ESI, go to: http://www.esi-group.com/casting/quikcast/success-stories

For more information on ESI’s Casting Simulation Suite, please visit: http://www.esi-group.com/products/casting