ProCAST

Virtual Modeling for Mega Casting

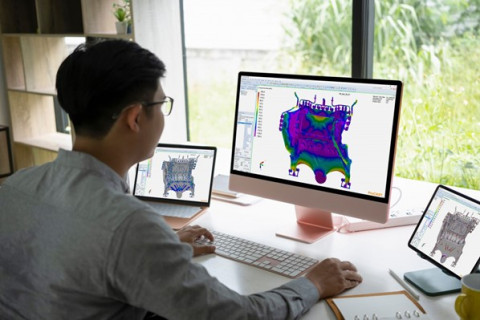

Achieving efficient die design is a challenge that requires a powerful, predictive casting simulation software. ProCAST is the solution, expertly handling large models including e.g. casting, die, vents, gating systems, shot sleeves, pistons, cooling channels, and ejector pins and every phase of the casting process —from die heating and filling to solidification and ejection—while ensuring a perfect match to performance standards.

- 35+ years of industrially proven, highly-scalable multi-physics solver for minimal turnaround times, supporting up to 32 cores (Windows)/ 64 cores (Linux) and customizable to handle flow, thermal, and stress simulations either together or separately as required.

- end-to-end process modeling for highly accurate predictions of key casting phenomena throughout the entire process, from dosing and filling to solidification, ejection, and quenching

- comprehensive integrated databases

- material database, including aluminium and magnesium alloys, integrating the COMPUTHERM thermodynamic database to automatically provide all required material data based on the alloy's chemical composition

- die casting machine database allows easy linking of piston movement to machine characteristics, ensuring accurate filling patterns crucial for predicting filling defects and flow speeds

- integrated FE flow and stress solver facilitates single model approach to model the entire high pressure die casting process in a single environment, eliminating the need to use different solutions for the analysis of filling, solidification, ejection and distortion.

- intuitive process-oriented workflows allow for fast and easy setup of simulations without the need to be a deeply trained numerical expert

- flexible token licenses to shift between graphical interface and solver, allowing to efficiently handle bottlenecks during the engineering phases

Virtual Modeling of Mega Casting with ProCAST Delivers

Better Designs and Fewer Defects

Optimize the strength, weight distribution, and manufacturability design, and identify potential weaknesses before production.

Improved Quality and Performance

Ensure the final product meets the desired mechanical properties and performance requirements by simulating The entire process from die heating until part ejection.

Cost Savings and Efficiency

Streamline the manufacturing process and drastically reduce the need for physical trial-and-error approaches to experience cost savings in terms of materials, labor, and time.

Accelerated Innovation

Explore unlimited design variations, material alloys, and process parameters without the limitations and cost of physical prototyping.

Confidently Master the Hottest Trend in Car Manufacturing with Mega Casting Simulation

Engineers and designers use ESI’s ProCAST casting simulation software to validate the entire casting process from die pre-heating, filling, solidification, in die cooling, part ejection, trimming, and out of die cooling:

Analyze the Part Alone

Quickly check castability and geometrical feasibility by analyzing critical thickness, thickness transition, draft angles, and last solidified regions, making part changes easy and inexpensive to accommodate.

Casting Validation

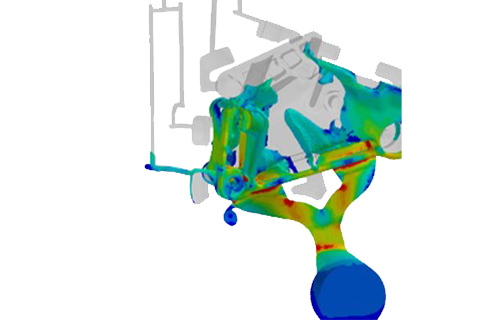

Optimize material behavior and process parameters by ensuring e.g. the molten metal remains liquid throughout the filling process, preventing material property variations, and enhancing gating and venting system designs to minimize air entrapment and shrinkage porosity, ensuring a defect-free casting.

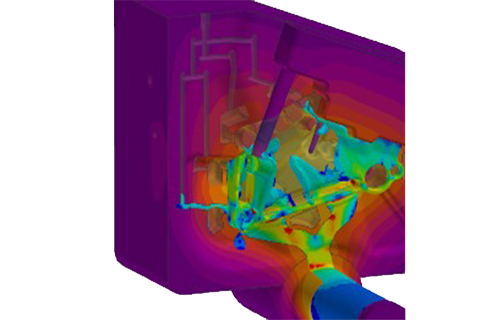

Accurate Gas-Fluid Interaction Modeling

ProCAST features an integrated two-phase flow solver that accurately models gas-fluid interactions, providing reliable predictions of local air back pressure. This capability is essential for optimizing cavity-filling patterns, especially in cases where venting design may not be ideal.

Xcelerate with Mega Casting — Shaping the Future of Body-in-White Design at Volvo Cars

Explore how Volvo Cars are switching to mega casting for their car bodies to simplify manufacturing, reduce weight, and improve safety. Read about their journey to bring Mega Casting functionality in-house, and how they use simulation to design for optimal manufacturability.

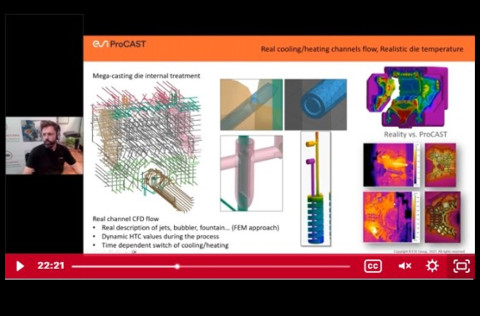

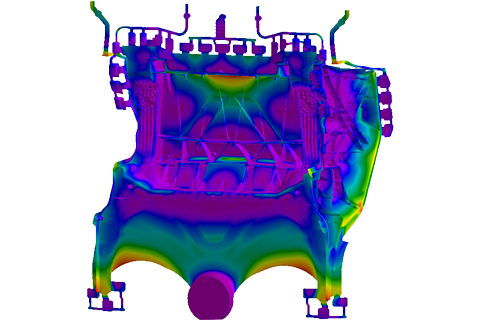

Mold Validation

Comprehensive tool design modeling, including cooling channels, dosing, shot piston, and thermal cycling effects, along with analysis of thermal and mechanical performance, enables the assessment of cooling rates’ impact on the part’s quality and structural integrity, particularly in thick and thin sections.

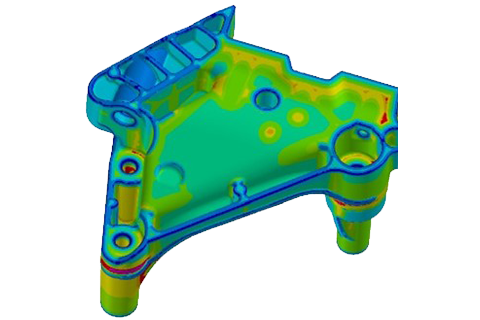

Accurate Deformation Forecasting

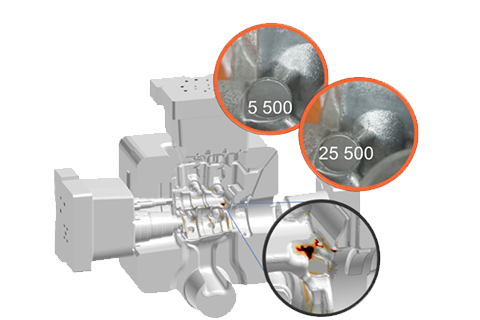

The finite element (FE) foundation makes ProCAST the best stress simulation software for castings and dies, providing accurate residual stress and distortion predictions, and die fatigue life assessments.

Die Fatigue Life Prediction

The accurate finite element stress solver evaluates both casting distortions and die fatigue life, crucial for minimizing the high costs of die manufacturing.