ESI releases Virtual Performance Solution 2012

ESI Group, pioneer and world-leading solution provider in Virtual Prototyping for manufacturing industries, announces the release of Virtual Performance Solution (VPS) Version 2012. Virtual Performance Solution enables ESI’s customers to virtually assess and optimize the overall performance of a future product at a very early stage of the design process. It cuts product development costs and time-to-market by reducing the number of physical prototypes, and by significantly improving the whole design process efficiency throughout the supply chain.

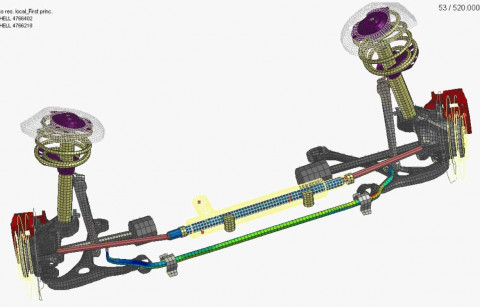

Dynamic Stresses in a suspension component Detail from a Virtual Prototype of a Full Vehicle

In various industries, manufacturers are striving to develop greener and safer products, using lighter materials and innovative designs, while ensuring leading-edge functional standards, including safety, comfort, NVH (noise, vibration and harshness), acoustics, stiffness and durability. VPS addresses all these key attributes and allows engineers to handle interactions across multiple - and sometimes conflicting - domains efficiently. Leading-edge accuracy is achieved in each domain by accounting fully for non-linear physics and manufacturing effects.

VPS enables efficient multi-domain optimization to master safety margins and lower product weight, reduce the number of physical prototypes, shorten design cycles and cut development costs. Featuring a single-core model for all domains of performance, and the ability to run all load cases on a single cluster, VPS reduces drastically the model conversion tasks and errors, and the lead times induced by synchronization between domains, in comparison to using multiple solvers on multiple hardware platforms.

VPS delivers outstanding performance for massively parallel computing for all domains of performance, and increases the overall workflow flexibility. The unified user environment for all domains (Visual-Environment) enables the management and the synchronization of the virtual engineering processes. Costs associated with multiple software installation and maintenance are reduced, and the efficiency of the whole engineering process is significantly enhanced.

Tomáš Kubr, CAE Manager ŠKODA Auto comments:“At ŠKODA Auto we have been using Virtual Performance Solution (VPS) for several years. Thanks to VPS we may be more efficient, using the same core model for crash, safety and linear statics. The One core model approach is already used for bonnet design and allows us to make better decisions about design changes in a reduced time cycle. We can benefit from this approach even more, which will allow us to introduce advanced chaining analysis such as springback after crash loads.”

Significant improvements in VPS 2012 specifically include:

- the modeling of non-linear phenomena for Strength and Durability;

- the modeling of highly damped components for Noise, Vibration & Harshness (NVH);

- the accuracy of airbag deployment for Safety;

- the handling of assembly pre-loads for all domains.

For more information on Virtual Performance Solution, visit our website: Virtual Performance Solution