ESI doubles revenues for its composites activity in 2011

ESI Group, pioneer and world-leading solution provider in virtual prototyping for manufacturing industries, announces that its license and services revenue linked to Virtual Manufacturing & Performance of composites has doubled over the past 2 years and tripled over the past 3 years.

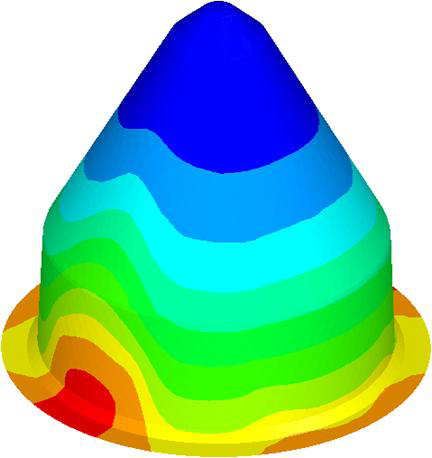

Courtesy of Professor Andrew Long, University of Nottingham

This success is the result of ESI’s continuous investment in Research & Development and the creation of a portfolio of software and services that successfully address the challenges of the manufacturing industries using composite materials. ESI’s Composites Simulation Suite, including software tools PAM-FORM and PAM-RTM, allows clients to fully plan & assess the manufacturing processes of their composite parts, while Virtual Performance Solution can predict the ‘in use’ performances of these parts.

Another contributing factor to this success is the deployment of ESI’s expertise across the globe:

- in Asia and in Russia, where the booming aeronautic sector requires innovative composite solutions;

- in Germany, where ESI provides expert knowledge in light-weight materials to the automotive sector;

- in Europe and South America, in support of the rapid advances in wind energy.

Ever since the opening of its dedicated R&D center near Bordeaux, the company has confirmed its commitment to strengthening its knowledge in composite materials by engaging in key partnerships with universities and industry players. Recently, ESI’s partnership with the University of Nottingham has resulted in the addition of a permeability database to ESI’s Composites Simulation Suite, allowing users to benefit from years of research in the field.

“We have worked with ESI on flow simulation, forming simulation and impact modelling for many years, and consider their software to be at the leading edge of composites analysis. During that time we have developed materials characterization techniques to determine necessary input data, in particular reinforcement permeability for resin flow simulation. We are very pleased to be able to provide some of our data for other users – as well as providing useful data for analysis of composites manufacturing. We hope that this will promote further collaboration amongst the composites manufacturing community,” declares Professor Andrew Long, Dean of the Faculty of Engineering, University of Nottingham.

Other key partnerships include a close collaboration with Universities of Dresden and IFB Stuttgart in Germany, the PPE (Pôle de Plasturgie de l’Est), Dassault Systèmes, and Chinese government’s aircraft consortium AVIC. To sustain its leading edge position in composites, ESI has also engaged in several French, German and European projects including MAAXIMUS, LYCOS, HIVOCOMP, INFUCOMP, LCM-SMART, RAID-OUTIL, MAI-composites or MAPPIC3D.

Recently announced funding from the French local government further encourages the company’s research activity. Last month, the Aquitaine region allocated 250 000 € to support ESI’s R&D center near Bordeaux. The center is located close to the “Aerospace Valley”, one of the world’s most important aeronautics R&D bases, where industry leaders such as Airbus, Dassault Aviation or EADS-Astrium are present.