What is System Simulation Software?

A Comprehensive Overview of System Simulation: Making Sense of Its Value and Applications with SimulationX

In today’s rapidly evolving industries, precision and efficiency are paramount. Engineers and designers across various sectors need to ensure that their systems operate seamlessly before they are built. This is where system simulation comes into play—a process that allows engineers to create virtual models of physical systems and analyze their behavior under different conditions. By simulating systems, you can predict performance, optimize designs, and troubleshoot potential issues long before physical prototypes are built.

System simulation is the use of software tools to model and analyze complex systems, which can include mechanical, electrical, thermal, fluid, or multi-physical domains. By utilizing mathematical models—such as finite element analysis (FEA) for structural simulations, or multi-body dynamics (MBD) for mechanical systems—engineers can mimic real-world scenarios and understand how components interact within the system.

Why Engineers Need System Simulation?

In today’s world of interconnected devices, cyber-physical systems (CPS) play a vital role in industries like automotive, manufacturing, and energy.

CPS integrate physical components—such as sensors, actuators, and mechanical systems—with digital control through embedded software. Examples include autonomous vehicles, smart grids, and industrial automation. To ensure that these systems work both reliable and efficient in real world operations, engineers use multiphysics system simulation software to model the behavior of each component and their interactions within the system as a whole. By doing so, they create virtual prototypes—digital representations of the physical system—which can be tested and optimized in a safe, virtual environment before any physical components are built. This approach is key to identifying design flaws early, reducing costs while ensuring seamless interaction between hardware and software.

Who Uses System Simulation and Modeling?

System simulation is a versatile tool used by various engineering roles to streamline processes, improve product designs, and enhance performance. Below is a matrix outlining key personas and how they benefit from system simulation:

| CAD Design Engineer | Integrates system models with CAD designs to ensure compatibility and optimize product structure. |

| Measurement Engineer | Validates simulation data against real-world measurements, improving model accuracy. |

| Library Developer | Creates simulation models and components for use in broader system analysis, ensuring accuracy and reusability. |

| Design Engineer | Simulates product performance early in the design phase to validate and optimize designs. |

| Calculation Engineer | Performs complex analyses and simulations to assess product behavior under different conditions. |

| Application Developer | Develops and tests application-specific software solutions based on system simulation results. |

SimulationX: The Powerhouse of System Simulation

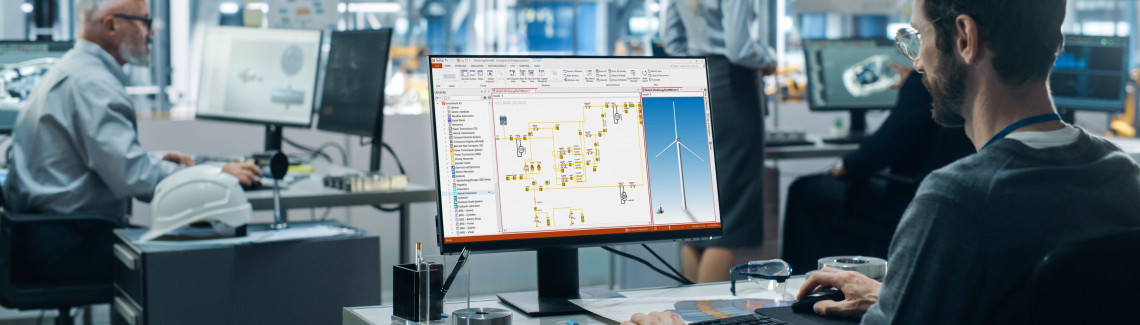

When it comes to system simulation, one of the most versatile and powerful tools is SimulationX. Developed by ESI, SimulationX is a comprehensive simulation platform designed specifically for modeling and analyzing complex systems. Its intuitive user interface and broad library of pre-defined components make it easy for engineers to model systems across multiple physical domains.

What Are Typical Applications Across Industries

SimulationX provides a comprehensive suite of applications across various domains, each tailored to address specific engineering challenges and optimize system performance.

What Are the Advantages of Using SimulationX for System Simulation?

SimulationX offers a range of powerful features and benefits that enhance the efficiency and accuracy of system simulation across various industries:

Multi-Domain Simulation: With SimulationX, engineers can simulate electrical, mechanical, hydraulic, pneumatic, thermal, and control systems in one unified environment, saving time and ensuring consistent results across domains.

Pre-Defined Component Libraries: The software offers a wide range of pre-built component models, including mechanical linkages, electrical circuits, and control algorithms, making it easy to build complex systems quickly.

Integration with Other Tools: SimulationX seamlessly integrates with CAD and PLM tools, enhancing collaboration and data exchange in the product development process.

Advanced Analysis Tools: Engineers can run transient analyses, frequency-domain studies, and non-linear simulations to better understand system behavior under various operating conditions.

Customizable Models: SimulationX allows customers to tailor models with scripting and Modelica, enabling precise customization to meet unique design and system performance requirements.

Flexibility: SimulationX offers seamless integration with CAD systems, ERP, and custom enterprise solutions through FMI and its open API, allowing for a highly adaptable simulation environment.

What are the Benefits of SimulationX Compared to the Different Other Types of System Simulation Software?

SimulationX customers value most the very comprehensive multi-domain environment. While there are excellent specialized tools e.g. for control system modeling, they usually lack depth in mechanical and thermal systems. Tools dedicated to structural analysis, are again highly specialized but don't provide the same level of fluid-structure interaction modeling that SimulationX does. Other strong multi-domain tools have similar modeling and simulation capabilities, but SimulationX is often preferred for its intuitive interface, which offers a more user-friendly experience, and its wide component library, making it a go-to solution for complex simulations.

SimulationX is optimized for high computational efficiency, allowing for faster simulations without sacrificing accuracy. Amongst our user base, engineers have reported reductions in simulation times of up to 30% compared to competing software, particularly in large, complex systems. Additionally, the accuracy of SimulationX’s non-linear dynamic analysis is considered best-in-class for multi-domain simulations.

Majid Nasrullah AzizProduct Marketing Manager at ESI Group

What is a Simulation Example for Component and Full System Level? See Real-World Use Cases at SimulationX User Conference 2024

SimulationX is pivotal in driving innovation across various industries by helping customers master the growing complexity in final performance validations at early design stages. Here are some notable real-world use cases where SimulationX has been instrumental in getting early confidence in the performance of large systems:

Automotive Engineering: TU Dresden uses SimulationX to revolutionize engineering efficiency through cyberphysical prototyping. Tata Motors leverages SimulationX for validating green, sustainable automotive transmission technologies and for gearshift simulation, specifically analyzing shift feel perception using Hardware-in-the-Loop (HIL) methods. IAV utilizes SimulationX to evaluate low-frequency NVH (Noise, Vibration, and Harshness) phenomena in electric vehicles, enhancing vehicle acoustics and comfort. Daimler Truck applies SimulationX for developing multibody systems models of trucks, crucial for advancing digital twin technology.

Space Exploration: JAXA and NewtonWorks Japan employ SimulationX for multidisciplinary concurrent design in reusable launch vehicles and spacecraft, integrating multi-physics modeling and simulation to achieve future space missions.

Machinery and Sustainability: Rexroth utilizes SimulationX to enhance sustainability in machinery through digital twins and system simulation. EA Systems applies SimulationX for analyzing system hydraulics in building energy supply, focusing on networked residential and industrial districts.

Mining Industry: INNOMOTICS employs SimulationX to create simulation models central to digital twins for copper ore mining operations, improving operational efficiency and resource management. The University of Waterloo, Canada, uses SimulationX to assess and redesign jackleg hammer drills, demonstrating how simulation drives improvements in mining equipment design.

Watch the SimulationX Conference 2024 on-Demand: Discover the Latest Software News and Application Examples.

Want to see and hear these groundbreaking use cases yourself?

Watch the SimulationX User Conference 2024 to

- experience these innovations live,

- learn about the latest software features,

- hear case studies from users at leading companies,

- and discover how SimulationX can help you solve even the most complex engineering challenges.

Don’t miss out on this opportunity to take your system simulation skills to the next level.

Denise is a seasoned media and communication professional with over 15 years of experience in the IT industry, spanning logistics and asset management software to system simulation and virtual prototyping (CAE & PLM). With a deep passion for technological innovation and sustainability, Denise is a steadfast ambassador and fervent advocate for Virtual Prototyping, utilizing her extensive expertise to steer companies through the conundrum of terminology in the era of digital and AI. As the Sr. Marketing Content Specialist at ESI, Denise creates insightful publications that help businesses understand the technologies, methodologies, and value of shifting from physical to virtual prototype testing – a transition that is facilitated through the utilization of CAE software, augmented with immersive tools and hybrid AI technologies.