SimulationX

Les systèmes techniques, comme les machines et les usines de production, sont souvent très complexes. Constitués d’une multitude de composants et de sous-systèmes reposant généralement sur des disciplines techniques différentes, ils intègrent de plus en plus de capteurs et d’organes de commande. Leurs interactions dynamiques ont une incidence majeure sur la sécurité, la performance et le confort.

SimulationX User Conference 2024: Watch Recordings Now!

Dive into digital innovation and system simulation technology with industry experts at the SimulationX User Conference 2024. This hybrid event features keynote talks, success-driven user presentations, networking opportunities, and exclusive updates from the SimulationX team.

Event Highlights at a Glance

- Keynote Talks: Explore transformative digital solutions.

- User Presentations: Learn from industry success stories.

- Exclusive Updates: Insights from the SimulationX core team.

For more details on abstract submission and participation, visit the event page:

Avantages de SimulationX

- Réduisez le temps de développement en utilisant des modèles pour tester rapidement les effets de diverses modifications de conception.

- Réalisez des économies en utilisant des prototypes virtuels plutôt que des prototypes physiques.

- Développez et testez le logiciel et le matériel de contrôle avec une usine virtuelle avant que le système ne soit construit (SiL, MiL, HiL).

- Réaliser des expériences approfondies basées sur la simulation pour identifier les problèmes de conception potentiels dès le début, lorsque le coût du changement est encore faible.

- Créer un jumeau numérique du système qui peut fonctionner parallèlement au système réel afin de surveiller l'état du système et d’identifier les défauts.

Costs & Time Saving

- Shorten development time by using virtual models to quickly test the effects of various design changes.

- Save design and iteration costs by front-loading design changes and validation of their impact and maximize the ROI.

- Reduce physical prototyping efforts and thus related cost and time.

- Carry out extensive simulation-based experiments to identify potential design problems early, when the cost to change is small.

List of Engineering Libraries Available in SimulationX!

Access a broad range of specific libraries and simulation models - all on one platform.

"Over the next 10 years, industries must advance to larger, more complex systems. Tools like SimulationX allow us to model these vast systems."

Francisco ChinestaScientific Director, ESI Group

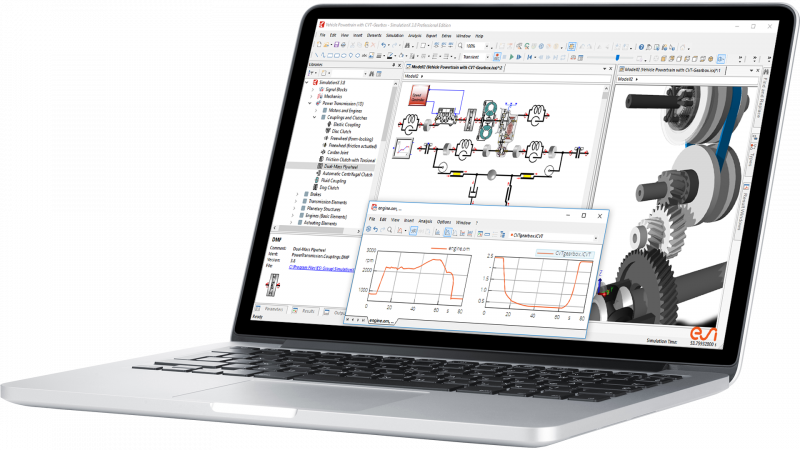

What are the Software Features that System Simulation and Modeling Engineers Appreciate Most?

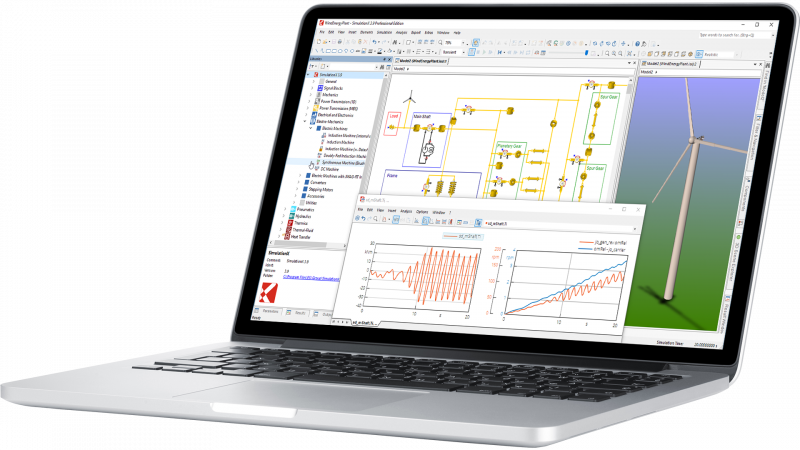

These are the main SimulationX software features that empower customers to shorten development cycles and front-load decisions on design changes by visualizing the state and performance of the whole system or parts of it:

Develop Next Generation Mobility Types With Full Virtual Vehicle Modeling and Simulation

Virtual prototyping and virtual testing are crucial in today's mobility industry because of their ability to meet increasing market demands and ensure products adhere to industry requirements and quality standards. When integrated into the design and engineering process, these tools enable customers to deliver innovative and scalable products. SimulationX leverages the power of 1D modeling, allowing for early design changes and validation. This approach ensures that results are transparent and accessible at any point in the development process.

By modeling and testing subsystems and other parts of the system like propulsion systems, energy, HVAC, electronics, and sensor systems as a whole, SimulationX facilitates comprehensive vehicle development.

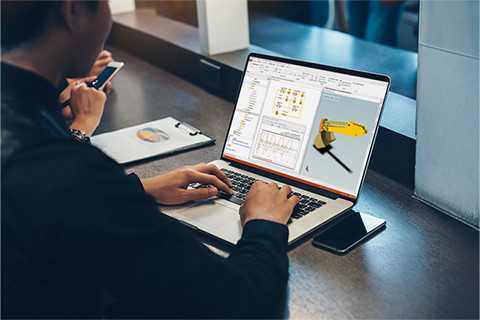

Improve Control, Precision & Effectiveness of Fluid Power Systems

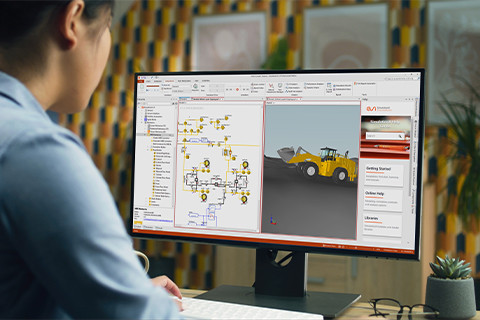

The complexity of fluid power systems is inevitable due to the involvement of fluid, mechanical, electrical, thermal & control systems all together. Depending on the application and industry, hydraulic or pneumatic systems are used to deliver high precision, faster response time, and high power density. In today’s mobility and machinery industries, fluid power systems play an important role in building versatile, durable, and reliable products.

With a legacy of modeling hydraulics & pneumatics systems accurately for years, SimulationX has a wide area of applications covered, spanning various industries. Modeling mechatronic systems in heavy machinery with hydraulic actuators and control units is one of the strong areas of SimulationX.

Identify, what is the best System-level Strategy for Effective Electrification & Energy Management

Complex requirements concerning energy efficiency, renewable energies, and electrification demand a solution approach that is safe, sustainable, and cost-effective. Especially automotive electrification technology is an emerging global trend. Producing, storage & distribution of energy using alternative energy sources like solar or hydrogen is gaining recognition in energy grids, the commercial and industrial space, as well as in heavy-duty transportation.

SimulationX delivers tailored solutions for EV battery range prediction, energy management, green hydrogen & alternate energy sources with its comprehensive library support and continuous development towards newer and innovative energy solutions.