Supercharging Crash Prediction & Validating Spot Weld Quality with Virtual Weld-Rupture Simulations | Webinar On-Demand

Caroline Bombart

caroline.bombart [at] esi-group.com (caroline[dot]bombart[at]esi-group[dot]com)

caroline.bombart [at] esi-group.com (caroline[dot]bombart[at]esi-group[dot]com)

Predict spot weld robustness accurately and enhance vehicle integrity

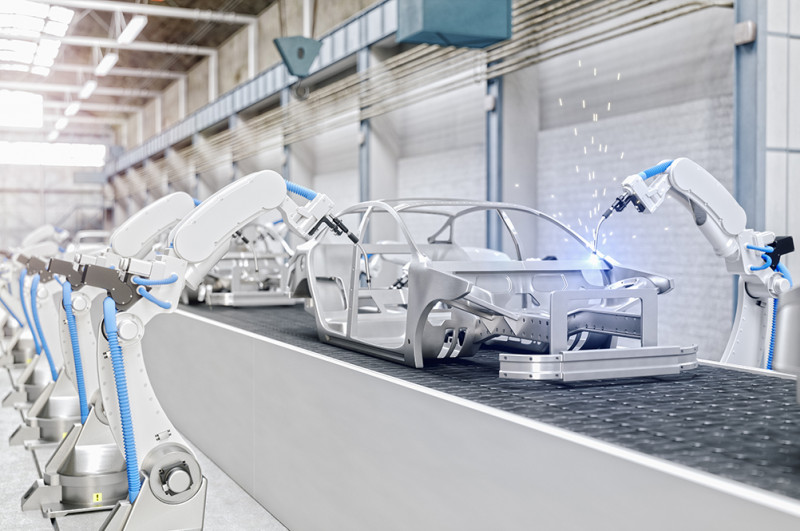

Automated spot welding is the primary joining method in high-volume manufacturing like the automotive industry. With a typical car containing over 3,000 spot welds of various types of alloys, steels, and galvanized sheets, OEMs must accurately predict their strength early on so they can ensure structural integrity, safety and prevent costly setbacks in later stages.

Given that the amount of spot weld combinations can easily exceed 1 million, it is therefore not realistic to assess the quality and joining strength of each individual spot as it would be too costly and time-consuming.

In this webinar, you will learn how:

- Control and optimize the spot weld process virtually to ensure the required weld characteristics.

- Easily check the robustness of the welding process through a weld lobe diagram.

- Integrate the welding history in virtual coupon rupture tests for more accurate prediction of force-displacement curves.