Overcoming Cabin Design Challenges for Autonomous Vehicles

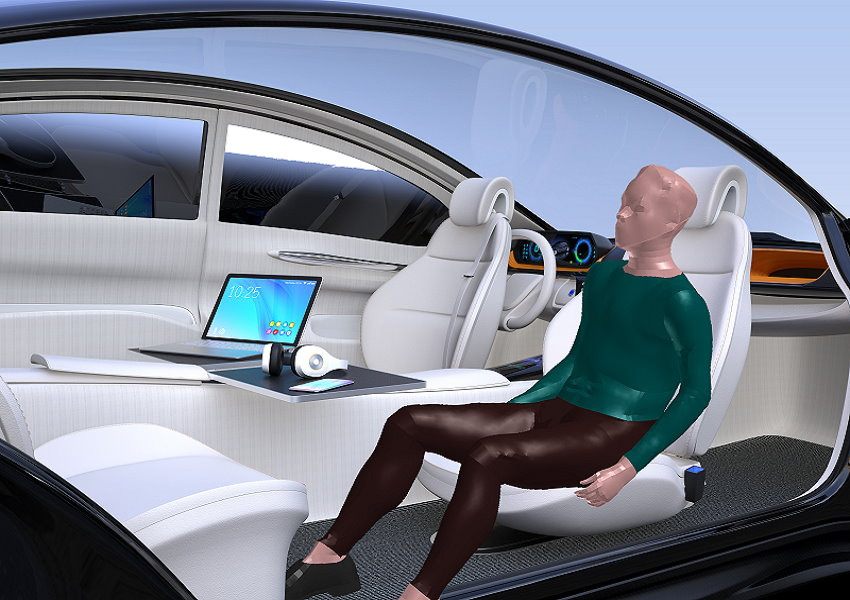

80% of OEMs plan to have autonomous cars on the road by 2025. This requires a complete reinvention of vehicle interior design. Passengers will be able to swivel around the cabin, obtain personalized climate control and better managed acoustics will be required. Discover how you can achieve optimum solutions while, at the same time, reduce the time and cost of product development.

Mobility is fast evolving. In recent years, we have rethought car usage to fit multiple uses supporting environmental and societal welfare, from car-sharing to electric, hybrid vehicles, and autonomous cars. With 80 % of OEMs planning to have autonomous cars on the road by 2025, automotive interior engineers must reinvent cabin design without ever compromising occupant comfort or safety.

Different use cases are emerging to allow both driver and passengers to interact differently, which can greatly impact the interior layout. Interior design and engineering teams must deliver new and innovative cabin designs and control their impact on various in-car systems. Teams need to iterate quickly and work towards optimum solutions on several scenarios without impacting the final delivery schedule.

With the prohibitive cost of hardware prototyping and associated delays, simulation is key to helping engineering teams face these new challenges. But how can simulation tools support concurrent work between teams seeking to fulfill different requirements? How can Virtual Prototyping help teams foster innovative solutions while mitigating the associated risks?

Developing radically disruptive solutions requires a radically different approach, ESI has a unique software solution dedicated to seats and cabin interiors, which empowers engineering teams to develop innovative designs with zero real prototypes. By building fully virtual prototypes that integrate all domains of physics, engineers evaluate all aspects related to occupant safety and comfort – including seating, thermal and acoustic comfort. They prepare for the certification of their asset virtually, and they do this early in the development process to benefit from maximum savings on development costs and maximum performance.

says Caroline Borot, who works on the development of Virtual Prototyping Solutions at ESI Group.

Maximizing Comfort while Minimizing Energy Consumption

The many heating and cooling systems present in the next generation of vehicles will have to satisfy the market demand for personalized comfort. Caroline Borot explains:

Nowadays, seat manufacturers want to give each person the ability to regulate individual heating and cooling systems, without imposing their own climate preferences on other occupants. This need will keep rising as we continue to progress towards a culture of car sharing.

On the other hand, automotive engineers must mitigate the impact of sophisticated climate-controlled seats on energy consumption. Having more efficient heating and cooling systems is key to extending battery range – and this places climate systems design under high scrutiny.

Seat engineers are striving to design intelligent systems adapting heat to different body areas and predicting passenger needs in different weather conditions, so that the climate management system delivers a better comfort for everyone and saves energy at the same time,

adds Borot.

The next challenge is to reach an optimum that works for varying cabin configurations.

Existing thermal systems cannot deliver desired thermal levels for the various available cabin layouts. Thankfully, simulation lends a helping hand to evaluate climate system performance for different cabin layouts and enables seat designers to do this at a controlled cost.

We spoke to Christian Marca, Product Manager at ESI Group, who says their Interior Solution addresses these problematics, allowing manufacturers to reduce the risk related to innovation:

Our software predicts realistically the seat and cabin thermal behavior and occupant comfort, and provides human models dedicated to comfort. With every part of the system modeled faithfully, the air movement and temperature fluctuation in the cabin can be predicted by CFD [Computational Fluid Dynamics] techniques, to provide continuously updated information and ensure the right thermal exchanges between the seat, the occupant and the cabin. For example, body thermal behaviors such as passive regulation and thermoregulation are taken into account to maximize the accuracy of results. Once the interactions between the seats, heating and cooling systems and passengers have been modelled, engineers are free to set thermostat rules and sensor locations, creating the air movement inside the cabin and temperature fluctuations. Doing all of this virtually really helps reduce the cost of design iterations later in the product development process.

Such advanced simulation solutions are becoming a cornerstone of seat development at leading OEMs. Last year at SAE WCX 18, Ford and ESI presented their collaboration for developing climate-controlled seats.

Achieving disruptive cabin designs without compromising safety

Highly automated driving features and autonomous vehicles bring tremendous freedom to totally reshape cabin design. The driver will spend less time driving, as automated driving features are implemented, and will enjoy more varied and relaxed positions. Front passengers will be free to swivel around the cabin at last. Backseat passengers may work or relax. The keyword is flexibility: a nightmare to ensure safety for all possible scenarios.

There again, simulation can be used to explore different options, and more specifically, virtual prototyping can deliver significant benefits to reduce the delays and cost of product development when working towards specific safety requirements. ESI’s Seat and Interior Solutions come with accurate seat modeling features including airbags and realistic seating of the dummy and keeps up to date with new regulations linked to autonomous technologies (new dummies, new standard protocols etc.). Building on decades of R&D in physics-based numerical modeling, the simulation results are fully reliable and trusted by engineers. Virtual seat and interior prototypes can be used for both safety and comfort evaluations, thereby supporting engineering teams in early decisions on interior concept and layout and significantly reducing the number of hardware prototypes.

Managing acoustics to keep private conversations private

Car sharing has become increasingly popular in the past decades. While this practice may help you reduce your travel costs and carbon footprint, there are downsides when sharing a ride, and one of them is privacy. The same goes for family trips when passengers disagree on musical choices, or simply wish they could sleep. To address these many issues related to sound, car manufacturers are working to create personal spaces within the vehicle cockpit. Engineering teams rely on sound technologies to offer occupants an immersive auditive experience, and this, wherever they sit. Moreover, with the advent of electric vehicles, new noises are now being heard as the engine noise is no longer present. Testing for and solving sound issues in several layouts would be very long and costly. With ESI Interior Solution, engineers can calibrate and test their sound system virtually to provide a high-quality experience in every interior design configuration.

Discover ESI Interior Solution at Autonomous Vehicle Interiors

For more information on this topic, head to https://www.esi-group.com/innovating-the-future-of-mobility

Céline produces content to shed some light on ESI and its customers. She enjoys reporting on topics related to innovation, digital transformation, and sustainability. She has a passion for technology and a taste for challenges.