Achieve superior sound quality of electrified luxury vehicles with an optimized acoustic environment

A technical look into how Bentley is developing an accurate, optimized, and cost-effective process to predict total vehicle aeroacoustic interior noise with minimal hardware testing

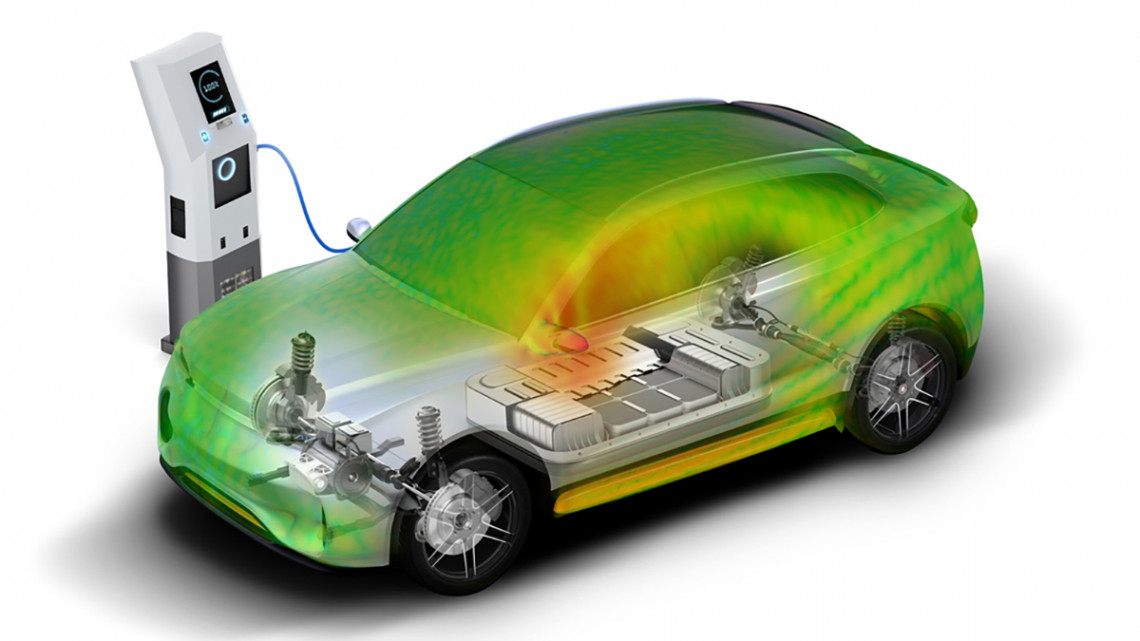

The rapid electrification of the automotive industry has altered the acoustic environment for many consumers. By removing the traditional internal combustion engine, you also eliminate its sounds, which in turn increases the importance of ‘masking’ noises like those generated by aeroacoustic sources. It’s hard for me to imagine but the reality is that even glazing panels make noise. With conventional cars and engine noise, it’s hardly audible, but the sound from glazing panels can be rather irritating when driving a quiet, electric vehicle.

Manufacturers in the luxury car segment are especially keen on spoiling passengers with the highest sound quality and refinement standards. Naturally, consumers in the luxury vehicle segment have minimal tolerance, if any, for a noisy interior cabin. Acoustic engineers work hard to predict all potential noise contributions; they study a multitude of source types and locations [1] and the paths on which noise is transmitted to vehicle occupants [2]. To quantify these sources and paths early enough in the development process to remove or mitigate their contribution without costly late design changes, acoustic engineers at Bentley have been relying on computational methods to predict whole vehicle aeroacoustic interior noise of new designs.

In 2021, my colleagues Joseph Venor and Simon Martin from our UK acoustics simulation team had the opportunity to contribute to a joint study with Bentley specifically targeting sound quality in the luxury vehicle segment. Their study presented the first phase aimed at delivering an accurate, optimized, and cost-effective approach to predicting whole vehicle aeroacoustic interior noise, early in the vehicle development process – and even more remarkably – reducing the reliance upon expensive prototype vehicles and minimizing the waste of natural ressources.

Let’s look at the scope of their work and share the key takeaways from the SAE technical paper.

Calculate interior noise with CFD + VA One for vibroacoustic simulation: a proven winning combination

A typical vehicle’s body structure can have as many as 100,000 modes (up to 8000Hz) and 250,000 modes for the interior cavities. Many millions of degrees of freedom are required to map the small wavelengths associated with these high frequencies. Deterministic methods are not able to handle such amounts of data, so to reach the higher frequencies of the audible range, a statistical approach is preferred [3]. As high-frequency amplitude variations are influential in the perception of automotive aeroacoustics [1], our research team concluded that a CFD and a statistical energy analysis (SEA) combined approach should be utilized.

After the team completed two CFD simulations, they exported the panel excitations into acoustic simulation software VA One. Following wavenumber frequency, spectra calculations for each panel were applied to a whole vehicle SEA model. The results from this simulation process were compared to the measurement data from a comparable wind tunnel test.

How can simulation provide the most optimal way to predict total vehicle aeroacoustic interior noise?

In a nutshell, the main objectives of this approach are:

- Developing a process to predict whole vehicle aeroacoustic interior noise performance

- Determining the absolute correlation of the method to a wind tunnel test

- Understanding the ability to model the effect of path modifications

- Assessing the possibility of implementing the method in a vehicle project (cost, time)

- Determining the panel contribution correlation to a wind tunnel test

The process outlined in SAE technical paper from Bentley Motors and ESI can be used as a guideline to predict the whole vehicle’s aeroacoustic performance for future vehicles. This approach enables OEMs to remove physical prototype vehicle testing at early stages where the vehicle shape can often be misrepresentative of the intended series design. Plus, this way of working is mission-critical for significantly reducing the likelihood of late, costly design changes.

Download the full SAE technical paper

Why statistical energy analysis is preferred over boundary element (BEM) and finite element method for aeroacoustics interior noise prediction

Statistical energy analysis (SEA) is an established methodology to perform interior noise and vibration prediction and sound and damping pack development [4]. In the automotive industry, SEA is widely used for sound package development and interior noise prediction. For this investigation, the acoustic simulation software VA One was used. The Statistical Energy Analysis module of VA One is the evolution of the industry-standard software for mid and high-frequency noise and vibration design, AutoSEA2. The SEA simulation module is routinely used in almost every industry for which sound and vibration are a concern.

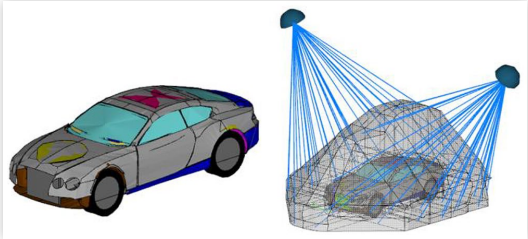

The luxury SEA model used was originally built to support sound pack analysis by considering structure-borne and airborne excitation from road noise and powertrain. The model was defined to provide the best understanding of the energy flow around and within the vehicle, enabling a large variety of analyses. The exterior sound field was comprised of near-field and midfield cavities, which were discretized to allow diffraction effects to be considered [5]. The midfield cavities were also connected to a semi-infinite fluid to represent an unbounded exterior acoustic space. The image on the left shows a visual representation of the whole vehicle SEA model structure (left) & its exterior sound field.

Physically validation confirms the high accuracy of numerical simulation results

Once all the analyses were complete, it was time to validate the accuracy of numerical data. To facilitate a comparison between the simulation method developed and physical test data, measurements were performed in the FKFS full-scale aeroacoustic wind tunnel [6], using a luxury coupé comparable to that modeled for the simulation activities. The wind tunnel moving belt system and vehicle wheels were both stationary, reflecting the CFD simulation. The test vehicle’s seals and ‘shutlines’ were taped (as shown in the image to the right) to remove the contribution from potential aeroacoustic leakages caused by gaps in the vehicle sealing system [7].

The research results in a nutshell: The total interior noise predicted via the CFD and SEA method correlated very well with the wind tunnel measurement.

- West, B. and Kendrick, P., “Automotive Aeroacoustic Sound Quality,” in Presented at The 12th FKFS-Conference 'Progress in Vehicle Aerodynamics and Thermal Management’, Stuttgart, Germany, 2019.

- Eberle, M., Schilling, R., Brennberger, M., and Wickern, G., “Statistische Energieanalyse der Windgeräusche am Kraftfahrzeug,” in Presented at Fortschritte der Akustik - DAGA 2008, Dresden, Germany, 2008.

- 3. Lyon, R. and DeJong, R., Theory and Application of Statistical Energy Analysis (Oxford: Newnes, 1994), ISBN:978-0-7506- 9111-6.

- Venor, J., Caillet, A., Martin, S., Marz, C. et al., “Using Statistical Energy Analysis to Optimize Sound Package for Realistic Load Cases,” SAE Technical Paper 2020-01-1525 (2020). https://doi.org/10.4271/2020-01-1525.

- Venor, J. and Zopp, A., “Using SEA to Model near Field External Sound Pressure Distributions Based on Automobile Geometry,” in Presented at Vibro-Acoustic Users’ Conference, Kiln, 2007.

- The Research Institute of Automotive Engineering and Vehicle Engines Stuttgart, “Wind Tunnels,” https://www. fkfs.de/en/test-facilities/wind-tunnels, accessed June 2021.

- Jagtiani, H., “The Objective Method of Evaluating Aspiration Wind Noise,” SAE Technical Paper 720506 (1972). HTTPS:// doi.org/10.4271/720506.

Natasha Baccari began her career with ESI in 2014, gaining unparalleled experience in the Virtual Prototyping space, while also establishing herself as a respected voice in the industry. As a content writer, Natasha is known for her expertise in taking technical facts and turning them into an easy-to-read story. When she isn’t writing success stories, she is focused on creating engaging content for the company’s website, blog and collaterals. While her writing currently focuses on software, Natasha started her career in medical writing when she published her own medical magazine for the public.