Worldwide

2:30pm CET / 8:30am ET

1h30

manuela.joseph [at] esi-group.com (manuela[dot]joseph[at]esi-group[dot]com)

Secure Casting Quality & Delivery Commitments

DIGITAL EVENT

On-Demand

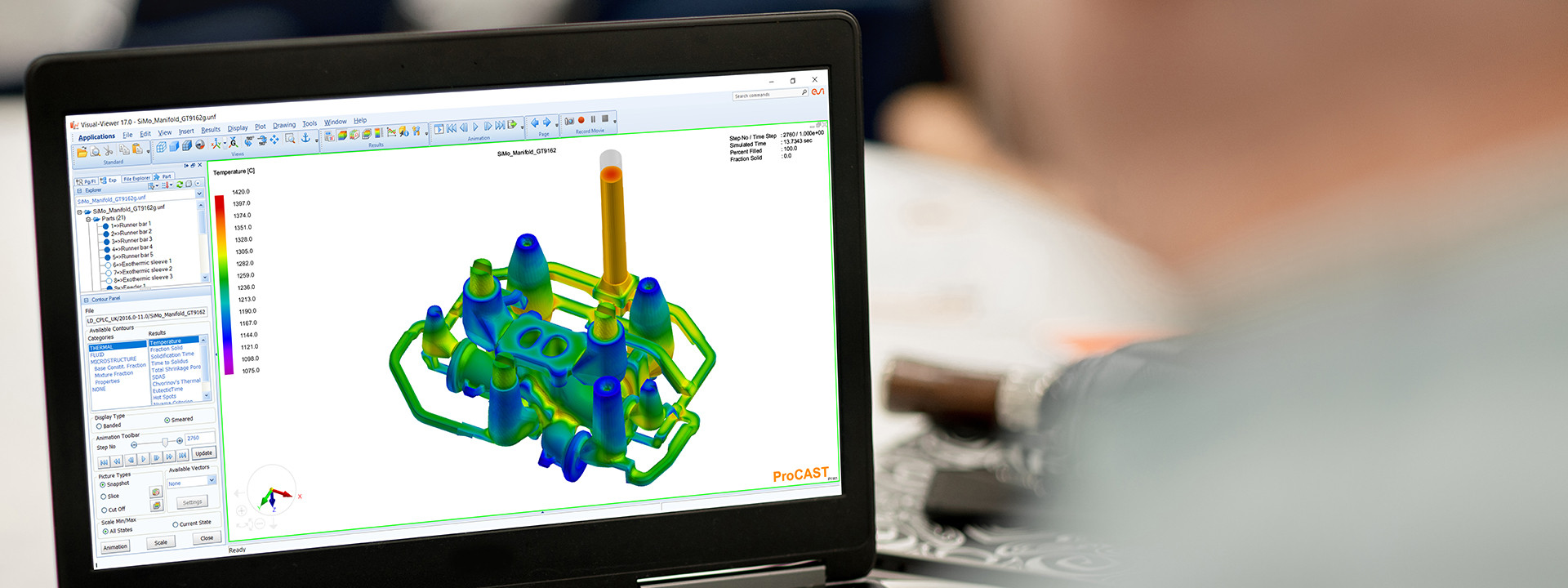

Simulation allows for virtual testing early on in the development stage. Accurate prediction and quantification of defects and process design are imperative in order to ‘get it right’ during production trials.

ESI welcomes you on June 21st to an event where we will discuss how digitalization is essential to ensure getting casting parts right the first time, meeting deadlines, and cutting costs on scrap parts or late redesigns. With its finite element technology, it also predicts complex issues like deformations and residual stresses and comprehensively addresses most castable alloys and most casting processes like sand castings, die castings, investment castings, and multiple variants associated with these processes.

During this exclusive digital event, learn from customers such as Kovolis Hedvikov, MCS and Azterlan, how they predict, analyze, measure, and avoid casting defects in the earliest stages of design. The event is digital and free of charge.

Agenda & Speakers

Introduction - Secure Casting Quality & Delivery Commitments

Customer Presentations

- Vlastimil Bryksi - HPDC "smart" die - future of casting quality and die fatigue control, Kovolis Hedvikov

- Susana Méndez - Disruptive 4.0 foundry models based on the knowledge economy, Azterlan

- Simone Gentiletti - HPDC Structural Component: Giga Tool innovative approach, MCS Facchetti

Panel discussion

Moderator: Badarinath Kalkunte, ESI Group

Panelists:

- Vlastimil Bryksi - R&D Head, Kovolis Hedvikov

- Aitor Loizaga - Coordinador de la línea de investigación de Materiales Férreos, Azterlan

- Simone Gentiletti - Engineering Manager, MCS Facchetti

- Lorenzo Valente - CEO, Ecotre Valente

Q&A