How to accelerate the Virtual Certification of your eVTOL with Model-Based Systems Engineering?

Create a digital thread supporting holistic verification and validation in next-generation air mobility vehicles

Current aerospace lifecycle challenges like continuous engineering, certification, distributed / collaborative development, consolidated verification platforms, homologation, and robust operational performance require well-informed decision-making in a comprehensive, reliable, traceable, repeatable, and customizable virtual environment. The tight collaborative ecosystem between integrators and suppliers, and the need for high safety levels require the capability of tracing each decision and its underlying artifacts. This capability becomes a key value for any engineering platform.

As shown in the figure aside, I’d like to focus on the example of simulation-based eVTOL certification credits, in order to introduce to you ESI’s middleware approach, enabling and supporting the Digital Thread while offering product development teams to perform early regulatory verification by virtually testing performance aspects, like lift-off verification and maximum eLoads on battery, or controller design.

5 Exemplary System-Level Requirements for eVTOL Design and Certification

From my engagement in various customer and research projects around aerospace development, the certification basis defined by authorities like EASA and FAA is very demanding for any eVTOL manufacturer – from a technical perspective, because of the new technologies, but also from an administrative point of view, because of the high safety levels. Let’s look at the specific regulations (proposals like MOC SC VTOL) that define requirements on performance and safety that need to be fulfilled for final certification:

1. Lift-off verification

“The thrust and drivetrain design should allow for lift-off at maximum takeoff weight of 1.6 tons (including payload) while maintaining maximum eLoads on battery and electrical system”

2. Maximum heat test

“The applied cooling system shall maintain safe temperatures in the battery under maximum load and most adverse conditions for at least 5 min”

3. Controller design for attitude and motion control

“The automatic flight control system shall be able to maintain attitude and follow a predefined trajectory within allowable deviations of 20 deg and 10 m, respectively under normal operating and given environmental conditions”

4. Battery component test

“Battery voltage drop for peak current (5 times maximum current) must stay below 200 V”

5. Emergency Landing in case of motor failure

“The automatic flight control system shall be able to detect an abnormal situation of a single rotor power loss of 20 % and execute a safe emergency landing under given environmental conditions”

Towards Certification via System Simulation and Model-Based Continuous Engineering Processes

Together with my colleagues, I presented a paper on this topic in May at VFS Forum 78, in Fort Worth, Texas, an established rotorcraft event. Using an exemplary eVTOL architecture, we introduced a solution that allows engineers to virtually verify the sizing and performance of new designs applying a model-based systems engineering (MBSE) methodology.

Major experiences and developments, empowering us to serve as a solution partner in this regard, have been made throughout our activity as a Core Partner in the CleanSky2 project MISSION. Here, ESI has been developing the technology of a software toolchain that supports seamlessly integrated workflows within aerospace design processes from requirements to certification, along the different levels of system decomposition (aircraft, system, component) and system integration. Before looking at the specific use case we presented, let’s briefly recap on the number one engineering challenge of the modern age: complexity – of systems and underlying processes.

- Certifying new technologies introduced right the first time is one reason for increasing complexity, particularly in the aerospace domain.

- Ensuring performance of the product and establishing trust in its behavior and safety prior to market launch and throughout the lifecycle is another reason.

- Finally, the ever increasing complexity of next generation mechatronic and cyberphysical systems themselves and OEMs’ commitment to increasingly virtualize development and test of new products with sustainable, low-emission practices add complexity on top of complexity.

However, being able to manage these levels of complexity shows the need to define methodologies like systems engineering – and the model-based derivates - that approach the system of interest in a holistic view. In order to effectively break any silos along the product lifecycle, such methods require a solid level of integration or chaining of data and processes. This is why modern product development itself is evolving towards a comprehensive, continuously engaged approach allowing engineers at all levels to make well informed decisions by virtually specifying, defining, simulating, and validating all artifacts.

Sample Use Case: Continuously integrated virtual eVTOL Performance Design and Verification

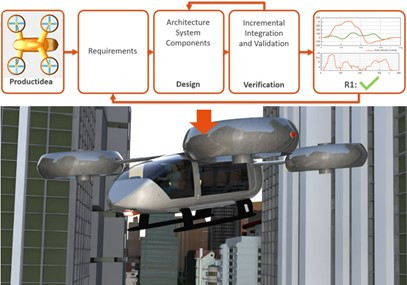

Let’s look at this new way of working then: in our presentation, my colleagues and I applied our tool agnostic digital thread integration technology, realizing MBSE methodology in order to enable virtual verification of all eVTOL system requirements, thus reducing development time and costs. In our sample use case, the goal was set to design a semi-autonomous eVTOL for an Urban Air Mobility (UAM) application with meaningful payload and endurance fulfilling certification regulations with respect to safety, performance, and comfort.

It’s a typical aerospace example where:

- Physical prototypes for design verification are very costly and time consuming

- Sensor design (for autonomous UAM) has to be verified within traffic and scenario simulation

- Simulation-based certification requires strong traceability between all artifacts

Since certification credits for complex systems with high safety levels and KPIs such as energy consumption estimation require integrative scenario-based testing (instead of “lab like” single system cycle testing), such use case is the perfect application of multiphysics system simulation.

In our example, leveraging ESI’s system modeling software SimulationX (even though we presented a tool-agnostic integration approach), we demonstrated that a baseline design did not meet the lift-off prerequisite. With modified blade airfoils and a higher lift to drag ratio, the improved design did match lift-off requirements but was not able to handle emergencies as requested. Finally, using an extended controller with different operating modes for specific emergency situations, the final design fulfilled all requirements.

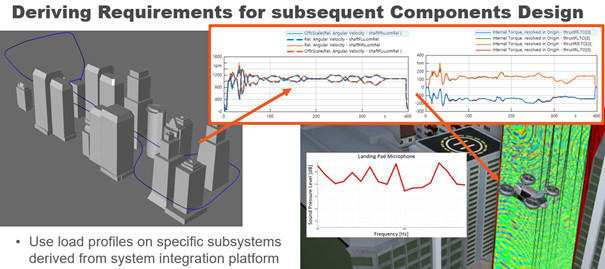

Hence, after some iteration loops verified by automatic virtual testing, the system architecture and sizing could be frozen and propagated across the whole digital thread. From a product development lifecycle perspective, main design decisions and analysis tasks like architecture exploration and sizing are based on non-geometrical simulations. With the increasing maturity level of the system under design, these results feed into geometrical, 3D design by specific component level requirements and load cases. ESI’s eVTOL demonstration drafted this data based, managed integration from 0D to 3D verification. All in all, we supported the chaining initiative by using the example of internal and external noise analysis, which was driven by performance simulation results as shown in the figure below.

To summarize, the holistic model-based engineering approach discussed here and demonstrated in the paper, depicts a certain part of the full lifecycle, where the system architecture, sizing and performance are defined - as critical steps most benefitting from an early stage, virtual verification. The analysis of these aspects under various environmental conditions is done within a wide range of “close to reality” test scenarios – this is especially recommended for those cases where physical prototype testing methods cannot serve sufficiently to support safety considerations like emergency handling.

Want to know more?

How does a vendor-neutral multitool platform implementation using model-based integration techniques allow aerospace companies to achieve fully traceable, early stage requirements verification by virtual testing? Which certification-relevant answers can engineers achieve by using system simulation software? Download our technical conference paper to get all the insights we shared here.

Graduated as an aerospace engineer, Marcel matured in compressor aerodynamics of jet engines (doctorate) before he joined ESI as a research associate for Systems Simulation. Still in charge of aerospace-related modeling and simulation topics, the core of his research activities moves continuously toward lifecycle integration topics applying model-based systems engineering methodology. Among various funded projects, like CleanSky2 MISSION, the outcomes feed directly into customer projects and prototypes for collaborative, continuous engineering platforms where Marcel represents the stakeholders' perspective supporting requirements and workflow definition to seamlessly integrate ESI solutions into established ecosystems.